The Harlech Stool

All is not what at first it seems

During the 2018/19 New Year holiday we visited Harlech in North Wales for a few days. We stayed in a tiny Airbnb cottage in the seaside town, which amongst other things, contained a rustic stool that caught my eye. I liked the proportions of it, so I took a few pictures and made note of where the top came up to on my leg, with a view to copying it later. In the absence of a tape measure, good enough would have to be good enough.

I wrote about this stool in my recent Chair Anthology post, where I described it as a cabinetmaking approach to a stool, due to the rectangular mortice and tenon joinery used. I seriously doubt any Welsh fisherman of the past was making his fireside stool like this. Any Welsh fishermen that remain today probably go to Ikea.

Charming though this rustic stool is, I’m entirely certain it’s faux-rustique. Take a close look at the left hand stretcher, which is round as though someone has stuck a length of branch in there, perhaps as a repair. But it still has the same mortice and tenon joinery. I smell a rat. And no-one wants to smell rat stool. The final nail in the prematurely-aged coffin came whilst I was making it. As I often do, I posted progress updates on Instagram. Someone (and I can’t remember who) sent me a picture of a guy they’d seen at a car boot sale, who had about 20 of these stools for sale. There were varying heights and sizes of stool arranged all around him. The game was up. Notwithstanding that, I still like the design and proportions of the stool, so the whoever the faker is, I think they have a reasonable eye. It takes about 30 seconds on Google images with the search term “Welsh stool” to find a rash of these stools at various retailers, mostly in crusty looking Elm. There’s clearly a workshop somewhere banging out quite a volume of ‘old’ stools for the buying public to consume. Maybe they’re made in “Far East Wales” as many fakes are. As a side note, they’re at a price that I wouldn’t make it for, so good luck to them.

On returning home I scaled from the photo, and my leg, to get a design on the page. You can download the drawing here. It’s more of a sketch to be honest, as it gives you the key dimensions, but doesn’t attempt to represent all the joinery. That part is on you. The process of working from a photo and some rudimentary details to get to a working design you can build from is a good discipline to learn, even if you might be copying a fake.

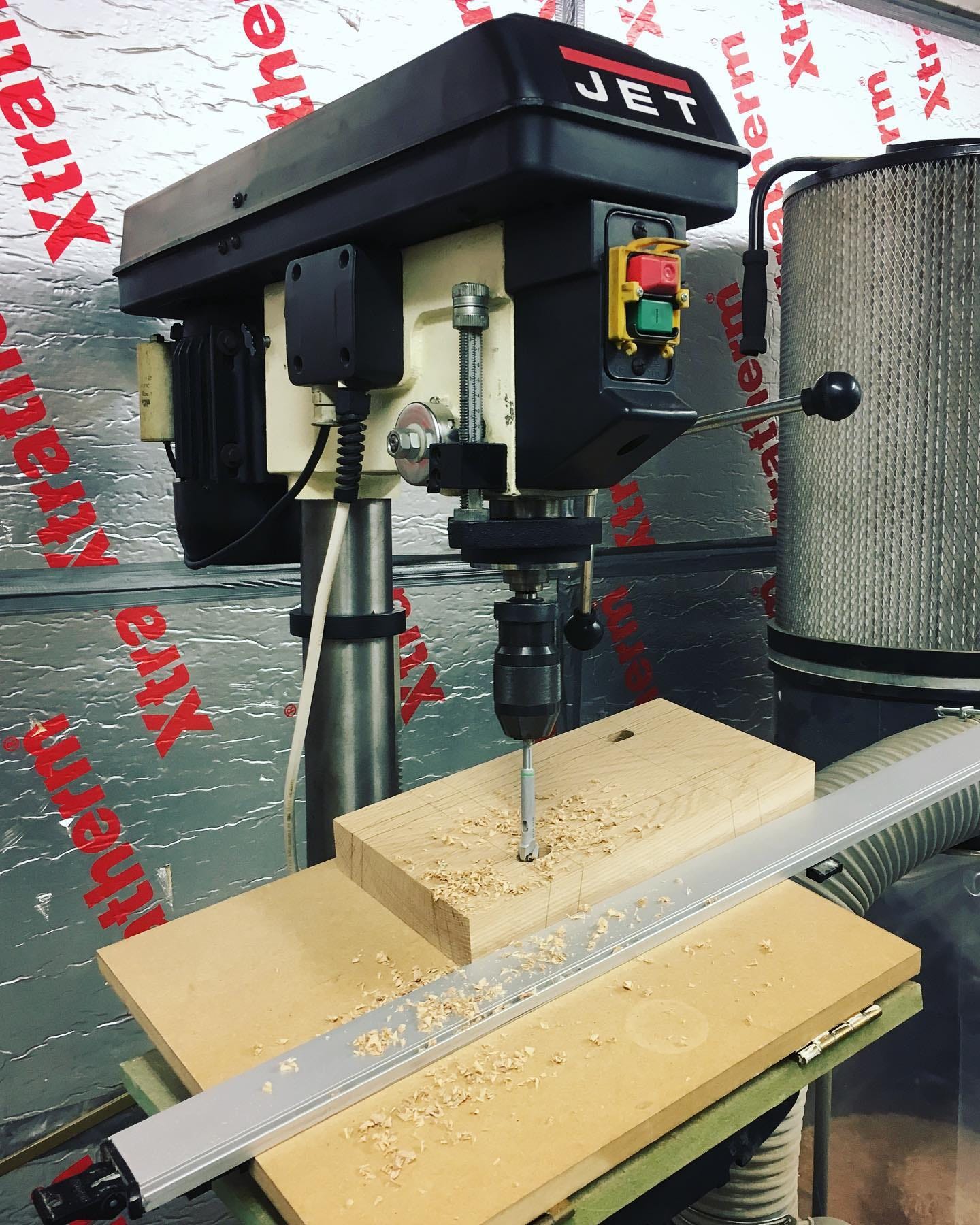

The legs of this stool are angled at 10 degrees off vertical in both directions, so the mortices in the seat become a compound angle. I drilled them using a fixture on the drill press table that is sometimes known as a banjo. Not sure why, as it’s just two bits of board joined by a hinge. This allows the tilt in the drill press table to provide the rake in one direction, and the banjo provides the splay in the other. You could equally well drill this from the underside like a chair leg, aligning the drill to a bevel gauge set to the resultant angle. Now that I’m confident with that approach, I would say it’s far quicker and easier than messing about with the drill press. Also I sold the drill press, so I can say with confidence I won’t be using that technique again any time soon.

Once the mortices are drilled, squaring them up by hand is the next step. You can see I drew myself some lines for both sides of the mortice so I chiselled in the right place. The exit wound is offset by 10 degrees in two directions from the entry wound.

I decided the simplest way to derive the tenon shoulder positions was to make the tenons with a temporary square shoulder, insert them into the mortices and scribe the angled shoulder from the underside of the seat. After that it was simple to saw the shoulders to the scribe line and chisel away the remaining material using the already established tenon cheeks as a jig.

If I recall correctly, I made the stretchers and then clamped them alongside their position on the legs to mark the tenon shoulders. At the same time I probably marked where I wanted the holes drilled for the mortices. A lot has happened since then and to be honest I can’t remember. I only have a tenuous hold on the whisps of last week’s memories , never mind four years ago.

This is fairly complex glue up, with 12 wedged tenons to deal with. There’s a need to spring the base apart a bit in order to get the top on, but I don’t recall it being too difficult. Once the glue has gone off you can rusticate to your liking. I knocked some corners off and gave the lowest stretchers a bit of accelerated foot wear, working with a block plane and spokeshaves. I chose to go with a texture on the seat, created with the travisher. I burnished the seat with some fine grit paper and shavings to try and highlight the texture. I think the Oak responds well to the approach.

If I’m honest I doubt I will make another stool like this. To my mind, a stool should be a cheaply and quickly made seat of necessity, and the work involved in all those rectangular mortices just doesn’t stack up. It does make an incredibly solid stool though. I tried to strike a balance of giving it a little character through eased edges, without making a pastiche of a genuinely old piece. I’ll continue to sit on it every day as I put on shoes before my daily walk. As I sit there I’ll reflect on the fact that I could’ve got one for £90 off Etsy, which looked as though it was made from fossilised rat turd that had been at the back of Welsh barn for 200 years.

I completely agree with your clear-eyed assessment of the original. The natives of Far East Wales were, and still are, in large degree, known for work like that. Not that there’s anything necessarily with that. When in Ikea, do as the Ikeans, I guess. Anyway.

The more I look at the stool, the more I’m struck by the (lack of) height of the longer stretchers. Just doesn’t look right to me. As a matter of fact, I think it’d probably drive me a little more nutso than I already am. Which, according to SWMBO, qualifies me for honorary membership in the local Squirrel Guild. All this certainly has more to say about my mental state than anything lastingly meaningful about art, design, or whatnot. But there it is.

The stools in our kitchen were purchased from a “hardwood furniture store” many years ago. On this side of the pond, stores selling full-on hardwood chairs, tables, stools, etc., often of oak, ash, or other relatively inexpensive, strong woods, used to be common. Designs were simple, if not rustic, and the selling points were “Solid oak!” (or whatever), and “Made in America”. Okay. Moving on.

The stools are certainly sturdy, having handled all sorts of duties with something akin to oaken aplomb. I’ve been waiting for them to wear out, break, or something for about thirty years, and I suspect they look at me with the same thought in mind. I’ve lately conceded that I’m gonna wear out or break before they do. My wife wants to know why I think I’ve not yet worn out or broken, the evidence showing that…. (It’s at about this point I surreptitiously take out my hearing aids, so I don’t have to listen to her presentation of Exhibits A through FF demonstrating the massive degradation in my state of being.)

But back to the stools, and why I decided to mention ‘em. I recently decided to paint ‘em, and went to the hardware store to look at buying some General Finishes Milk Paint. And there I discovered what might be the last quart of GF Blue Moon Milk Paint for sale in the Western Hemisphere. So, regardless of all else, the stools will be a dollop of that lovely color in our kitchen for probably the next thirty years. Or however long we last.

Thanks so much for your additional thoughts and sketch of this little stool. For sure the tenons reflect the skill of an advanced woodworker and not a piece from the Ikeans. Knowing the angles and your use of a “banjo” on the drill press will help a lot. Since I still have a drill press (and a banjo) I will use that technique for getting the mortises started.