After my recent experiences on The Schoolbox with handtool-only stock preparation, I’ve been thinking I needed a lighter Jack Plane. The Lie-Nielsen 5 1/2 I use is a very nicely made plane, but damn is it heavy*. It weighs in at 7lb 4oz according to my scales, which is heavier than my son was when he was born. Or three and three quarter bags of flour. It’s a nice plane to use in general terms, but when it’s being used as a true Jack, the mass is a handicap. What I mean by a “true Jack” is not just the size, but a plane with a heavily cambered blade, being used to hog off material in the early stages of stock preparation. Part of the reason for the weight of the 5 1/2 is the additional width, but for Jack work that width is irrelevant. With a heavily cambered blade only the middle part is projecting, so a wider plane offers no real advantage. The big downside is the fatigue using a heavier plane causes, plus I’m not really looking to develop Popeye-like forearms.

*I feel there is a perception in modern toolmaking that mass = quality in hand planes. There might be something in that when it comes to smoothers (although even there I’m not totally sure the evidence bears that out) but for some planes, improving our ability to wield them comfortably might be worth more. When it comes to the larger planes, a closer eye on weight would probably benefit us all. Especially those with weedy forearms like me.

So I’ve been keeping an eye on eBay for the last couple of months, waiting for the right plane to come along. What defines “the right plane” is a moot point, but I suppose I meant a fairly cheap one as I didn’t want to commit too much money to this experiment. I also didn’t have the appetite for the search to go on for too long, so the “right” plane became the “right now” plane. In the end it was a cheeky offer to the seller on a plane which didn’t sell that led to my purchase. For the cost of a Chinese takeaway I bought myself a Stanley No.5. And I still had the Chinese food too - reckless in these straightened times I know.

I’m not really a keen tool fiddler, so I bought a plane that needed minimal intervention to become usable. I didn’t want one that anyone else had messed about with. At my price point the plane was always going to be a more recent model, which is generally associated with lower manufacturing quality. I did some detailed research to date the plane. Actually I just read what someone had written on the box “HBD FROM M&D 1/12/81”. I decoded this to mean Happy Birthday from Mum and Dad, 1st December 1981. Sharp detective work I know. So I surmise this plane was probably made in the 1970’s, just like me. The era has a reputation for poorly executed work and a general lowering of standards. I’m doing what little I can to fulfil that destiny.

This No.5 is a Made in England plane. Although Stanley were based in Sheffield, 30 miles North of here, the plane castings were made even closer to home. The presence of a “Q” on the frog tells me that this planes castings were made at the Qualcast Foundry in Derby, only 15 miles down the road. I believe the machining was still done in Sheffield. None of that means it’s any good, but it’s kind of interesting.

It was clear that the plane had barely been used, so whoever received it for a birthday gift clearly didn’t take to woodwork. I reckon I spent 45 minutes readying this plane for use. Probably half an hour longer than the original owner spent planing with it.

The plane bore fairly coarse surface grinding marks and still had the original protective coating on the sole and sides. I gave it a light sanding with 180 grit paper to clean it up, removing a little rust in the process and slightly refining the surface. I haven’t bothered checking it’s flatness as it really doesn’t matter for what I’m doing.

The planes arrises were factory sharp, so I slightly rounded these over.

I cleaned the casting, checking under the frog too. Then I re-fixed the handle and knob, which were loose when it arrived. The handle and knob are in good nick, I think they’re Beech, covered with a thick and shiny Teriyaki-like coating. Maybe the original owner liked Chinese food too.

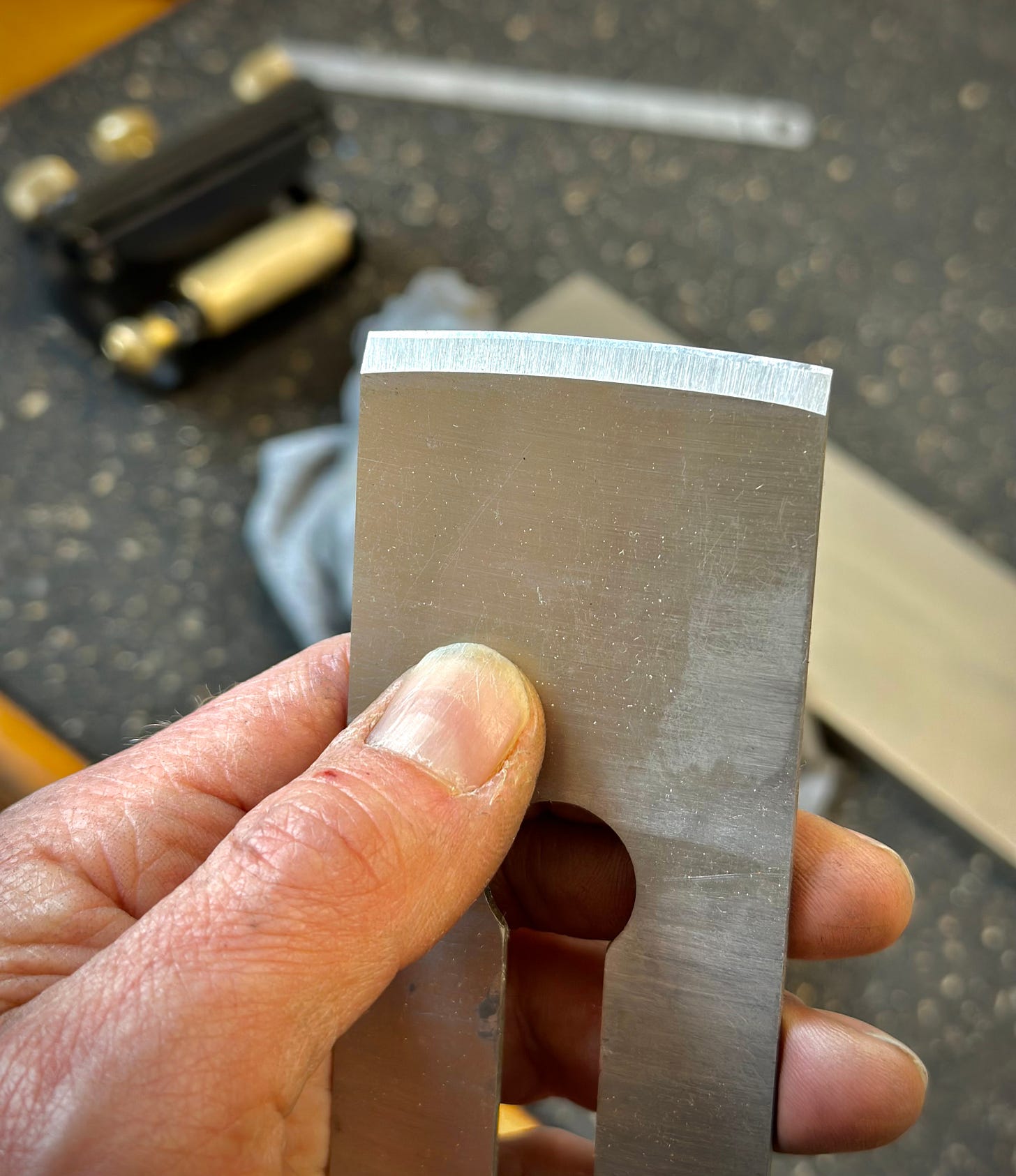

The blade still had the factory grind on it, which gives some idea of the limited use it had received. I wanted to grind away the first bit of steel to remove any poorly heat treated material, plus add a nice camber. I’m happy with the camber on my 5 1/2, so I just laid that on top and drew round it with a Sharpie, then ground to the line. I grind at 25 degrees and hone at 35. That’s somewhat steeper than Stanley used to recommend for their blades, but I’ll give it a try and see how it holds up. The blade hones easily and the steel is clearly softer than the A2 I’m more used to, which might mean edge durability is limited. We shall see.

I gave the chip breaker a little love, flattening the edge where it meets the blade and polishing up the curve a bit.

I took the sharp edges off the upper parts of the blade and chip breaker, so that when my index finger rests on the side of them it isn’t uncomfortable.

And that’s it. Ready to go.

In use it performed nicely and the lighter weight was really noticeable. This Stanley No.5 weighs in at 4lb 14oz, so that’s nearly 2 1/2 lbs lighter than the Lie-Nielsen. I’ll be putting it to work in the coming months and will report any further findings as they happen. And if the blade turns out to be no good, I’ll fold the foil takeaway containers double and stick that in there. I believe that’s how they do some plane blades nowadays.

Agreed with the weight-loss program. It's why I've developed an interest in japanese planes. Woodies are great with laminated blades but the western varieties are at least 150 years old. Understanding of tool steel has improved significantly in those years. The laminated blades in Japanese planes leverage some of that info. Buying new can be pricey but getting a used plane can be cheap. Kind of like a checklist when you take a used car to a mechanic to check it out before purchasing, I'm working on a blog post about a checklist for japanese planes with some case studies. Right now finishing a blog post on evaluating some japanese chisels.

For the same reason (weight), I purchased a used Sargent #3416 from Hyperkitten. It was not expensive, but the finish of its handles did not remind me of any Asian sauces. I think the style is called transitional. The body is wooden, but the guts are metal. After spending a fair amount of time fettling the cap iron/chip breaker to make it mate with the cutting iron, it seems to work pretty well for the jack-planey tasks I have given it. I want to get a camber on the blade but I don’t have a grinder so I’m hoping that I can get there by sharpening a la Schwarz. I’m an amateur, so take this with a fair pinch of salt.